Induction heating basics

Induction heating and its influencing factors as well as our range of services in this area are presented briefly and concisely below.

What is induction heating?

Induction heating offers numerous advantages over conventional heating mechanisms. It is a direct process. The heat is therefore generated in the workpiece itself and does not have to be introduced via its surface. In addition to a very high level of efficiency, almost unlimited power densities are theoretically possible, which means that very short heating times can be achieved. However, the most important advantage in favor of induction heating is the high process reliability and heating quality.

The range in which the electromagnetic field acts in the material - also known as the penetration depth δ - can be specifically influenced via the frequency (see illustration). This allows a desired heating profile to be set precisely, which is particularly important for induction hardening.

Dependence of the penetration depth on the frequency with inductive heating

Influencing factors for induction heating

In addition to the frequency-dependent penetration depth, the efficiency of induction heating depends on various influencing factors: the material parameters, the design of the coil, the power and quality of the converter and the temperature change of the part to be heated required for the application.

Electrically insulating or conductive material

Induction heating usually requires an electrically conductive material. However, non-conductive materials, such as plastics, can also be heated indirectly by first coupling a conductive metal as a susceptor and then transferring the heat to the non-conductive material.

Permeability

Until the Curie temperature is reached (the temperature at which a magnetic material loses its magnetic properties), magnetic materials have a particularly high electrical efficiency. This is due to two effects: On the one hand, the lower penetration depth causes a higher impedance - the system is said to have a higher impedance. On the other hand, additional hysteresis losses occur in magnetic materials due to the permanent magnetic polarity reversal of the material. Magnetic materials only lose this advantage when the Curie temperature is exceeded. Due to this non-linearity, the inductive heating of magnetic materials requires a great deal of experience when designing and planning an induction system.

Geometry

As 85% of the power is converted in the penetration depth range, the frequency must be selected so that the ratio between the diameter and the penetration depth corresponds approximately to a value of 3.5. Otherwise, the temperature must be equalized inside the material only via thermal conduction, which leads to unnecessarily long heating times for components with a large diameter or poor thermal conductivity.

Electrical resistance

For efficient induction heating, the specific electrical resistance of a material is one of the most important influencing factors, which can be illustrated in a simple way. According to Joule's law, there is a proportional relationship between the converted power P and the product of the electrical resistance R and the current strength squared:

![]()

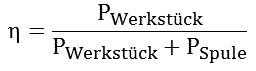

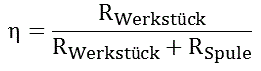

By definition, the electrical efficiency η is the quotient of the total power of the process and the power converted in the workpiece. If the losses on the supply lines and the electrical components of the power supply are neglected, the total power can be expressed as the sum of coil losses and the power introduced into the workpiece:

Using Joule's law, the efficiency can be directly related to the electrical resistance:

Coil design

The heart of induction heating is the induction coil. Every induction heating process requires the development of an individual coil design. A high-quality induction system requires both in-depth expertise and many years of experience in coil design in order to meet the process requirements in terms of heating quality, throughput and efficiency.

Induction heating has many advantages over conventional heating methods

Compared to conventional heating processes, for example with gas or oil, one of the most important advantages of induction heating is the excellent process control and reproducibility. While the energy content of fossil fuels is subject to natural fluctuations, which affects the heating process, the final temperature of an induction system can be controlled to the second within a specified time.

These and other advantages are leading to a steadily growing market share in the use of induction technology. Induction heating is far from having exhausted its great potential in the foreseeable future, despite continuous further development and the opening up of new areas of application.

The main areas of application for induction heating can be divided into the following areas:

Induction systems for heating to forming temperature

Induction preheating is one of the classic applications of induction heating. Short cycle times with high heating quality can be achieved both with stationary material and in continuous throughput.

Induction heating of trays and belts

Two different processes are used for induction heating of sheets and strips, depending on the thickness of the workpiece: longitudinal field and transverse field heating. Very high power densities can be generated with both processes, which means that very fast heating times can be achieved.

Induction hardening

Induction surface hardening is a process for increasing fatigue and wear resistance and the associated static strength. A particular advantage of inductive surface hardening lies in the precise adjustment of the hardening profile via the frequency and the inductor geometry in conjunction with the use of field concentrators.

Induction welding

The main application of induction welding relates to the longitudinal seam welding of pipes. The process is suitable for all types of steel and non-ferrous metals as well as for round and rectangular profiles and enables high throughputs with outstanding quality.

Inductive annealing

Induction annealing is ideal for removing coarse or uneven microstructures, internal stresses or for easier machining and shaping. The most important advantages are the high temperature accuracy and uniformity.

Inductive soldering

In induction soldering, a workpiece is heated up to the working temperature of the solder, which is applied to the solder joint either manually or continuously. Due to the very short heating times, the surface of the solder joint remains oxide-free, resulting in a very good solder joint.

Inductive melting

Induction melting is a widespread field of application for induction heating. A distinction is made between crucible induction furnaces and channel-type induction furnaces. Crucible induction furnaces are mainly used for melting and are characterized by good automation capability, high operating performance and good stirring capacity. Channel-type induction furnaces are mainly used as holding furnaces or for melting non-ferrous metals. The greatest advantage is the very high electrical efficiency in the range of 95 % to 98 %.

Better heating results thanks to modern numerical calculation methods

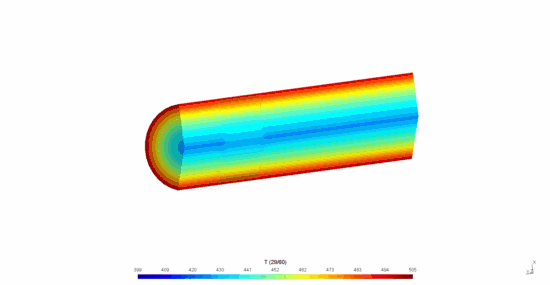

Inductive heating of a round bolt

The development of a new product, production process or technical solution involves a combination of experience, theoretical background knowledge and the right tools. We combine sound specialist knowledge from research and industrial practice with computer-aided methods. Numerical simulations have established themselves as an indispensable tool, particularly in the design of modern induction systems. Earlier empirical calculation methods are not able to capture the complex physical relationships and meet today's requirements in terms of economic efficiency and product quality. Furthermore, only by using numerical simulations is it possible to gain a detailed insight into an inductive heating process and to eliminate errors or undesirable effects as well as to carry out optimizations.

Our services

With our extensive expertise in the field of numerical simulations of inductive, structural-mechanical, fluid and thermodynamic processes, we are able to model even complex processes and design them with high precision. This enables us not only to evaluate the success of feasibility studies and preliminary developments, but also to produce concrete designs of the end product.

We are happy to provide support both in an advisory capacity and in actively solving technical problems.

Our services include the following in detail:

- Carrying out a market analysis

- Draw up specifications

- Developing conceptual solutions

- Creating the design

Distribution of induction systems and components

We sell individual solutions, complete systems and spare parts for the following areas:

- Generators and IGBT converters

- Induction heating

- Inductive hardening

- Inductive melting.

The products on offer meet all current standards and safety regulations and have proven themselves to international customers in terms of durability and quality!

Optimization of heating, hardening and melting processes

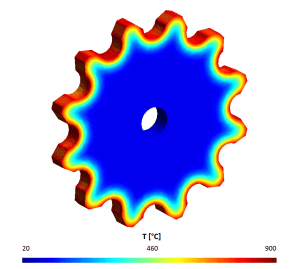

Induction heating for surface hardening

In order to successfully optimize a product or process with regard to quality or production costs, data on the physical influencing factors is of crucial importance. Empirical studies can only fulfill this requirement to a limited extent. For this reason, the acquisition of measurement data is often incomplete due to inaccessible measuring points or extreme demands on the equipment, or uneconomical for time and financial reasons due to the considerable effort involved. In contrast, a much more efficient method is based on the use of computer-aided investigations or numerical simulations. In this way, parts, components or entire production processes can be simulated and detailed information can be determined. The data obtained in this way can be used to identify and improve weak points. In this context, the use of parameterized models makes it possible to examine many different variations while using few resources. This type of optimization can be transferred to many other areas.

Get in touch with us

We specialize in the analysis, planning and optimization of induction systems, inductive processes (e.g. induction heating or induction hardening) and manufacturing processes. For further information or queries, please contact us by telephone on 06202 8598456 or by email: info@eltatech.de.