What are the advantages of induction hardening?

Induction hardening is a special field of induction heating. The heat generated in the workpiece by induced eddy currents can be applied to a component in a targeted manner and with high precision. Induction hardening can generate the highest energy concentrations, which enables very short cycle times and high throughputs.

How does induction hardening work?

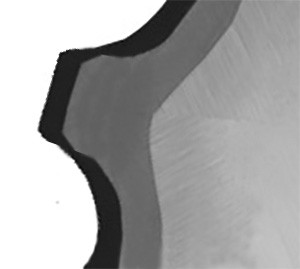

Induction hardening enables a precisely defined hardening contour

By selecting the right frequency, the penetration depth of the electromagnetic field can be adjusted in a targeted manner so that heat build-up is achieved up to the desired hardening depth. This means that almost any hardening process can be achieved within the range of possibilities offered by the material. The currents flowing in the workpiece are caused by a voltage induced by an inductor based on the transformer principle. The inductor is the primary winding and the workpiece is the (short-circuited) secondary winding. The higher the selected frequency, the more pronounced the skin effect. The local distribution of the heat sources generally corresponds to a first-order Bessel function for cylindrical workpieces; only at high frequencies can this Bessel function be replaced by an exponential function. This applies to non-magnetic metals and austenitic and ferritic steels in the temperature range above the Curie point (768°C). The penetration depth is a measure of the skin effect. Within the penetration depth, 86% of the total power is converted into heat. For example, for steel at a temperature of 800°C at a frequency of 10 kHz, the penetration depth is 5 to 6 mm. Below the Curie point, the penetration depth at 10 kHz is less than 1 mm and the distribution of the heat sources corresponds approximately to a parabola. However, the skin effect is not the only decisive factor for the temperature curve across the cross-section; depending on the heating time, some of the heat flows away from the surface layers to the inside of the workpiece as a result of heat conduction. High frequency and high power density on the surface of the workpiece result in a steep temperature gradient. By selecting a low power density, very flat temperature curves can also be generated; the frequency can be lower in this case. Different working methods have been developed for induction hardening due to the different arrangement of the workpiece and inductor as well as different relative movements between the two, whereby a distinction is essentially made between hardening without feed and with feed.

What should I bear in mind when induction hardening?

In addition to rapid heating to austenitizing temperature, spraying and cooling are of crucial importance. The duration of spraying, the correct shape of the nozzle and the choice of the right medium require a great deal of experience and process-specific know-how.

Can hardening also be combined with induction tempering?

In principle, inductive tempering can also be used. It should be noted that the frequency is selected lower for inductive tempering and therefore a larger mass is heated. As a rule, a longer heating time is required for tempering than for hardening.